Spring Washers

--------------------------------------------------------------

You Are Here -> Home ->Washers->Washers Type->Spring Washers

JF Engineering has been manufacturing Spring Washers since 2004 & shipped to more than 60 Countries Like Argentina, Germany, Mexico ,Vietnam, Indonesia, USA , Saudi Arabia, UAE, Egypt , Turkey, Venezuela, Italy, Singapore, Malaysia, Australia, New Zealand, Canada & many more.

JF Engineering has been manufacturing Spring Washers since 2004 & shipped to more than 60 Countries Like Argentina, Germany, Mexico ,Vietnam, Indonesia, USA , Saudi Arabia, UAE, Egypt , Turkey, Venezuela, Italy, Singapore, Malaysia, Australia, New Zealand, Canada & many more.

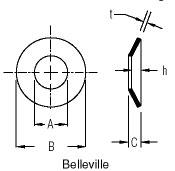

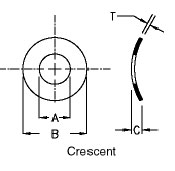

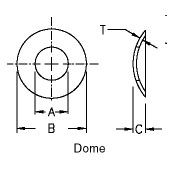

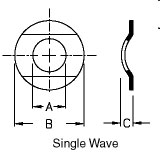

Spring washers, sometimes called disc springs, are a subtype of washers.Spring washers are specifically designed to provide a compensating spring force and sustain a load or absorb a shock. Many design variations have evolved to best serve one or the other of these two basic functions or to optimize both functions in a single part within specific I.D./O.D. limits.

We Manufacture Spring Washers in vareity of material including Stainless Steel,Alloy Steel,Carbon Steel,low Carbon Steel,Copper & Copper Alloys,Nickel Based Alloys & other special alloys on request.

Orders at JF Engg are guaranteed fast delivery of the Spring Washers in the country. The main reason being we have an excellent warehousing and storage facilities for both finished and semi finished goods.They are made ready as per the urgent requirements of the customers. The Spring Washers are manufactured to sustain very high pressure and product warranty.In 2015 we have stocked more than 188 tons of Spring Washers in all sizes, to cater to immediate delivery and urgent needs of the clients. For small requirements we can dispatch the Spring Washers immediately against the purchase order.

There are six primary instances of spring washers.

|

|

|

|

|

|

|

|

|

|

|

|

DIN/ISO Standards For Spring/Split/Lock Washers

DIN 127 |

DIN 128 |

DIN 137 |

DIN 6796 |

DIN 6904 |

DIN 6905 |

DIN 6908 |

DIN 7980 |

JIS B1251 |

BS 4464 |

DIN 3063 |

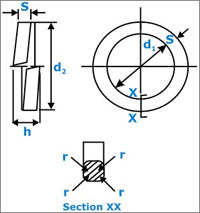

Spring Washers Dimensions

| Nominal Size | Inside Diameter | Thickness | Outside | ||

| and Thread | d1 | and | Diameter | Radius | |

| Diameter | Width | d2 | r | ||

| d | max | min | s | max | max |

| M3 | 3.3 | 3.1 | 1+0.1 | 5.5 | 0.3 |

| (M3.5) | 3.8 | 3.6 | 1+0.1 | 6.0 | 0.3 |

| M4 | 4.35 | 4.1 | 1.2+0.1 | 6.95 | 0.4 |

| M5 | 5.35 | 5.1 | 1.5+0.1 | 8.55 | 0.5 |

| M6 | 6.4 | 6.1 | 1.5+0.1 | 9.6 | 0.5 |

| M8 | 8.55 | 8.2 | 2+0.1 | 12.75 | 0.65 |

| M10 | 10.6 | 10.2 | 2.5+0.15 | 15.9 | 0.8 |

| M12 | 12.6 | 12.2 | 2.5+0.15 | 17.9 | 0.8 |

| (M14) | 14.7 | 14.2 | 3+0.2 | 21.1 | 1.0 |

| M16 | 16.9 | 16.3 | 3.5+0.2 | 24.3 | 1.15 |

| (M18) | 19.0 | 18.3 | 3.5+0.2 | 26.4 | 1.15 |

| M20 | 21.1 | 20.3 | 4.5+0.2 | 30.5 | 1.5 |

| (M22) | 23.3 | 22.4 | 4.5+0.2 | 32.7 | 1.5 |

| M24 | 25.3 | 24.4 | 5+0.2 | 35.7 | 1.65 |

| M27 | 28.5 | 27.5 | 5+0.2 | 38.9 | 1.65 |

| M30 | 31.5 | 30.5 | 6+0.2 | 43.9 | 2.0 |

| (M33) | 34.6 | 33.5 | 6+0.2 | 43.9 | 2.0 |

| M36 | 37.6 | 36.5 | 7+0.25 | 52.1 | 2.3 |

| (M39) | 40.8 | 39.6 | 7+0.25 | 55.3 | 2.3 |

| M42 | 43.8 | 42.6 | 8+0.25 | 60.3 | 2.65 |

| (M45) | 46.8 | 45.6 | 8+0.25 | 63.3 | 2.65 |

| M48 | 50.0 | 48.8 | 8+0.25 | 66.5 | 2.65 |

Ready Stock

Surface Coatings

General Queries While Buying Spring Washers

- High rejection rate

- No control on quality and testing

- Non availability

- Late deliveries

- Poor packaging/ Unprofessional Packing

- Poor after sales service

- Supply of wrong grades

- Material inconsistent with ASTM Standards

- Very hard material for use

- Poor surface finish

- No Mill test report

- Dubious Practices

- Lack of knowledge

- Product fails under high pressure

- High pricing of the goods due to supplier commission

Why Choose JF Engg. While Buying Spring Washers?

- High pressure sustainability

- Impeccable surface finish

- Product replacement warranty

- After sales support and service

- World class buying experience

- Very quick delivery

- Mill test report/ Digital Mill test report in accordance with EN10204 NACE 3.1, NACE 3.2

- 3rd Party inspection

- Government and Private Laboratory Testing

- Test certificate from ISO 17025 Standards Laboratory

- Same day shipping of the goods

- Highest stock in the country

- Stringent Quality Testing and Control

------------------------------------------------------------------------------------------------------------------------------

For More Information About Spring Washers please call +91 22 2385 6385 / 2385 638 or send an email to info@jfengg.com