You Are Here -> -> Exotic Alloy Fasteners -> Nickel Alloy Fasteners -> Nickel 201 Washers

Manufacturer of comprehensive range Nickel 201 Washers in Excellent Quality with low price

Manufacture one of the widest ranges of Nickel 201 Washers in India at Best Factory Rate

JF Engineering has been manufacturing Nickel 201 Washers since 2004 & shipped to more than 60 Countries Like Argentina , Germany , Mexico ,Vietnam , Indonesia , USA , Saudi Arabia , UAE , Egypt , Turkey , Venezuela , Italy , Singapore , Malaysia , Australia , New Zealand , Canada & many more.

The Nickel Alloy Fasteners offered by us are manufactured using superior grade of metals. These industrial nickel alloy fasteners exhibit sturdy construction, precise dimension and high tolerance level. Our fasteners are manufactured with accurate dimensional for easy installation and removal. We can offer industrial nickel alloy fasteners in variety of specifications as per the requirement of the clients

when the task calls for Nickel 201 fasteners , call for JF Engg. Nickel 201 can be hot formed to almost any shape. The temperature range 1200°F to 2250°F is recommended and should be carefully abided as the proper temperature is the most important factor in achieving hot malleability. Full information of the forming process should be sought and understood before proceeding.

Nickel 201 can be cold formed by all conventional methods, but because nickel alloys have greater stiffness than stainless steels more power is required to perform the operations.Nickel 201 is the low carbon version of Nickel 200 . It is preferred to Nickel 200 for applications involving exposure to temperatures above 600°F. With low base hardness and lower work-hardening rate, it is particularly suited for cold forming.

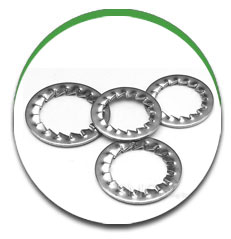

We Manufacturer premium quality standard & customized washers from various metals & metal alloys as per ASTM/ASME/DIN/DIN Standards & Specifications.We produce all types of Nickel 201 Washers in almost all shapes & sizes.We also provide passivation,quality coating further processing as per client's requirement.

Orders at JF Engg are guaranteed fast delivery of the Nickel 201 Washers in the country. The main reason being we have an excellent warehousing and storage facilities for both finished and semi finished goods.They are made ready as per the urgent requirements of the customers. The Nickel 201 Washers Nickel 201 Washers Nickel 201 Washers immediately against the purchase order.

Specification

Material

Size

Length

Specification

Manufacturer

GKW

Unbrako

Kundan

APL

Sundaram Precision

EBY Fastener Etc.

Note:-

Material:

Hastelloy,.Cupro Nickel, Nickel, Monel,Inconel, Alloy 20 Etc.

Standard :

ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472

Nickel Alloy in Grade:

UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 8020 (ALLOY 20 / 20 CB 3)

Type of Fasteners:

Bolts : Bolts stud bolts, hex head bolts, socket hexagon head screw anchor bolts, u-bolts, J bolts, mushroom head square neck bolts, t- head bolts, wing screw, eye bolt, eye bolt, foundation bolts and structural bolts

Washer : Plain washer , plain big & small OD washer , spring lock washer , spring washer heavy duty , tooth washer , star washer , tab washer with one & two tab

Nuts : Hexagon nuts, hexagon coupling nuts, hexagon thin nut, square nut, hexagon castle nuts, self locking nut, hexagon domed cap nuts

Screw : Pan head slotted screws, cheese head slotted screws, countersunk head slotted screws, countersunk raised head slotted screws, pan phillipse head screw, countersunk Phillipse raised head screws, slotted cheese trim head machine screws, socket head allen cap screws, allen countersunk socket head cap screws, socket head shoulder screws, socket head cap screw low head, hexagon socket set screw with flat point, hexagon socket set screws with cone point, hexagon socket set screw with dog point, hexagon socket set screws with dog point, hexagon socket set screws with cup point, imprial socket cap screws.

Other : Threaded rod, as per drawing and customers spec. coating, hot dipped galvanizing, phosphate, Teflon, xylon, zinc, cadmium.

In Form of:

Hex, Square, Round , Threading as per Gauge Etc.

Washers Type

Grade Designation

Standard

Nickel 200

Nickel 201

UNS

N02200

N02201

Werkstoff Nr.

2.4066

2.4068

Nickel 201 Washers Useful Info

Chemical Composition

Typical compositional ranges for Nickel 201 Washers

Nickel 201

Ni

99.0 min

Fe

0.4 max

C

0.02 max

Mn

0.35 max

Si

0.2 max

Cu

0.25 max

Mg

0.15 max

Ti

0.1 max

S

0.01 max

Mechanical Properties

Typical mechanical properties for Nickel 201 Washers

Density

8.9 g/cm3

Melting Point

1446 °C (2635 °F)

Tensile Strength

Psi – 67000, MPa – 462

Yield Strength (0.2%Offset)

Psi – 21500, MPa – 148

Elongation

45 %

Nickel 201 Washers Price

Nickel 201 Washers Inventory

---------------Nickel Alloy Washers-------------

washers nickel 200 flat washers

washers nickel 200 plain washers

washers nickel 200 standard washers

washers nickel 200 bolt washers

washers nickel 200 washers

washers nickel 200 spring washers

washers nickel 200 steel washers

washers nickel 200 lock washers

washers nickel 200 metric flat washers

washers nickel 200 stainless steel flat washers

washers nickel 200 fender washers

washers nickel 200 machine washers

washers nickel 200 hardened washers

washers nickel 200 apartment size washers

washers nickel 200 lock washer sizes

washers nickel 200 star washers

washers nickel 200 flat washers

washers nickel 200 washer flat

washers nickel 200 brass flat washers

washers nickel 200 teflon flat washers

washers nickel 200 copper flat washers

washers nickel 200 lock washer and flat washers

washers nickel 200 flat washer manufacturers

washers nickel 200 brass flat washers

washers nickel 200 flat washer and lock washers

washers nickel 200 custom flat washers

washers nickel 200 galvanized flat washers

washers nickel 200 neoprene flat washers

washers nickel 200 cut washer vs flat washers

washers nickel 200 nord lock washers

washers nickel 200 locking washers

washers nickel 200 split lock washers

washers nickel 200 washer lock

washers nickel 200 serrated lock washers

washers nickel 200 bearing lock washers

washers nickel 200 star lock washers

washers nickel 200 wedge lock washers

washers nickel 200 thick washers

washers nickel 200 thick flat washers

washers nickel 200 extra thick washers

washers nickel 200 extra thick flat washers

washers nickel 200 bolt washers

washers nickel 200 washer and bolt

washers nickel 200 nut bolt and washers

washers nickel 200 bolt nut and washer

washers nickel 201 flat washers

washers nickel 201 plain washers

washers nickel 201 standard washers

washers nickel 201 bolt washers

washers nickel 201 washers

washers nickel 201 spring washers

washers nickel 201 steel washers

washers nickel 201 lock washers

washers nickel 201 metric flat washers

washers nickel 201 stainless steel flat washers

washers nickel 201 fender washers

washers nickel 201 machine washers

washers nickel 201 hardened washers

washers nickel 201 apartment size washers

washers nickel 201 lock washer sizes

washers nickel 201 star washers

washers nickel 201 flat washers

washers nickel 201 washer flat

washers nickel 201 brass flat washers

washers nickel 201 teflon flat washers

washers nickel 201 copper flat washers

washers nickel 201 lock washer and flat washers

washers nickel 201 flat washer manufacturers

washers nickel 201 brass flat washers

washers nickel 201 flat washer and lock washers

washers nickel 201 custom flat washers

washers nickel 201 galvanized flat washers

washers nickel 201 neoprene flat washers

washers nickel 201 cut washer vs flat washers

washers nickel 201 nord lock washers

washers nickel 201 locking washers

washers nickel 201 split lock washers

washers nickel 201 washer lock

washers nickel 201 serrated lock washers

washers nickel 201 bearing lock washers

washers nickel 201 star lock washers

washers nickel 201 wedge lock washers

washers nickel 201 thick washers

washers nickel 201 thick flat washers

washers nickel 201 extra thick washers

washers nickel 201 extra thick flat washers

washers nickel 201 bolt washers

washers nickel 201 washer and bolt

washers nickel 201 nut bolt and washers

washers nickel 201 bolt nut and washer

Nickel Alloy Fasteners

Nickel 200 Finished Hex Nut

Nickel 200 Forged Nuts

Nickel 200 Heavy Nuts

Nickel 200 Hex Bolts

Nickel 200 Hex Head Bolts

Nickel 200 bolt

Nickel 200 eye bolts

Nickel 200 nuts

Nickel 200 u bolts

Nickel 200 Stud bolts suppliers

Nickel 200 lag bolts

Nickel 200 metric bolts

Nickel 200 toggle bolts

Nickel 200 countersunk bolts

Nickel 200 UNC bolts

Nickel 200 Hex Nuts

Nickel 200 B7 Studs and 2H Nuts

Nickel 200 Studs

Nickel 200 SS bolts

Nickel 200 Hexagon Head Bolts

Nickel 200 Hexagonal Bolt

Nickel 200 Hexagonal Nut

Nickel 200 Stud Nuts

Nickel 200 Gasket Nuts

Nickel 200 Long Nut

Nickel 200 Machine Nuts

Nickel 200 Stud Bolts

Nickel 200 T Bolt

Nickel 200 T-Nut

Nickel 200 Pipe Nut

Nickel 200 Dome Nuts

Nickel 200 Bolts

Nickel 200 Cap Nuts

Nickel 200 Slotted Nuts

Nickel 200 Square Head Bolts

Nickel 200 Stainless Bolt

Nickel 200 Nut

Nickel 200 Steel Nuts

Nickel 200 Structural Bolts

Nickel 200 Machine Screws

Nickel 200 Machine Washers

Nickel 200 Bolt Fasteners

Nickel 200 Resistant Screws

Nickel 200 Cap Screws

Nickel 200 Sheet Metal Fasteners

Nickel 200 Socket Cap Screw

Nickel 200 Spring Washer

Nickel 200 Square Head Screw

Nickel 200 Pipe Cap

Nickel 200 Stud Anchors

Nickel 200 Industrial Fasteners

Nickel 200 Washer

Nickel 200 Metal Fastener

Nickel 200 Metal Washers

Nickel 200 Plain Washers

Nickel 200 Star Washer

Nickel 200 Hexagon Head Screws

Nickel 200 Special Drawings

Nickel 200 Hex Screw

Nickel 200 SS screws

Nickel 200 Flat Washers

Nickel 200 Hex Head Screws

Nickel 200 Hex Nipples

Nickel 200 hex cap screws

Nickel 201 Studs

Nickel 201 SS bolts

Nickel 201 Hexagon Head Bolts

Nickel 201 Hexagonal Bolt

Nickel 201 Hexagonal Nut

Nickel 201 Stud Nuts

Nickel 201 Gasket Nuts

Nickel 201 Long Nut

Nickel 201 Machine Nuts

Nickel 201 Stud Bolts

Nickel 201 T Bolt

Nickel 201 T-Nut

Nickel 201 Pipe Nut

Nickel 201 Dome Nuts

Nickel 201 Bolts

Nickel 201 Cap Nuts

Nickel 201 Slotted Nuts

Nickel 201 Square Head Bolts

Nickel 201 Stainless Bolt

Nickel 201 Nut

Nickel 201 Steel Nuts

Nickel 201 Structural Bolts

Nickel 201 Machine Screws

Nickel 201 Machine Washers

Nickel 201 Bolt Fasteners

Nickel 201 Resistant Screws

Nickel 201 Cap Screws

Nickel 201 Sheet Metal Fasteners

Nickel 201 Socket Cap Screw

Nickel 201 Spring Washer

Nickel 201 Square Head Screw

Nickel 201 Pipe Cap

Nickel 201 Stud Anchors

Nickel 201 Industrial Fasteners

Nickel 201 Washer

Nickel 201 Metal Fastener

Nickel 201 Metal Washers

Nickel 201 Plain Washers

Nickel 201 Star Washer

Nickel 201 Hexagon Head Screws

Nickel 201 Special Drawings

Nickel 201 Hex Screw

Nickel 201 SS screws

Nickel 201 Flat Washers

Nickel 201 Hex Head Screws

Nickel 201 Hex Nipples

Nickel 201 hex cap screws

Nickel Alloy 20 Studs

Nickel Alloy 20 SS bolts

Nickel Alloy 20 Hexagon Head Bolts

Nickel Alloy 20 Hexagonal Bolt

Nickel Alloy 20 Hexagonal Nut

Nickel Alloy 20 Stud Nuts

Nickel Alloy 20 Gasket Nuts

Nickel Alloy 20 Long Nut

Nickel Alloy 20 Machine Nuts

Nickel Alloy 20 Stud Bolts

Nickel Alloy 20 T Bolt

Nickel Alloy 20 T-Nut

Nickel Alloy 20 Pipe Nut

Nickel Alloy 20 Dome Nuts

Nickel Alloy 20 Bolts

Nickel Alloy 20 Cap Nuts

Nickel Alloy 20 Slotted Nuts

Nickel Alloy 20 Square Head Bolts

Nickel Alloy 20 Stainless Bolt

Nickel Alloy 20 Nut

Nickel Alloy 20 Steel Nuts

Nickel Alloy 20 Structural Bolts

Nickel Alloy 20 Machine Screws

Nickel Alloy 20 Machine Washers

Nickel Alloy 20 Bolt Fasteners

Nickel Alloy 20 Resistant Screws

Nickel Alloy 20 Cap Screws

Nickel Alloy 20 Sheet Metal Fasteners

Nickel Alloy 20 Socket Cap Screw

Nickel Alloy 20 Spring Washer

Nickel Alloy 20 Square Head Screw

Nickel Alloy 20 Pipe Cap

Nickel Alloy 20 Stud Anchors

Nickel Alloy 20 Industrial Fasteners

Nickel Alloy 20 Washer

Nickel Alloy 20 Metal Fastener

Nickel Alloy 20 Metal Washers

Nickel Alloy 20 Plain Washers

Nickel Alloy 20 Star Washer

Nickel Alloy 20 Hexagon Head Screws

Nickel Alloy 20 Special Drawings

Nickel Alloy 20 Hex Screw

Nickel Alloy 20 SS screws

Nickel Alloy 20 Flat Washers

Nickel Alloy 20 Hex Head Screws

Nickel Alloy 20 Hex Nipples

Nickel Alloy 20 hex cap screws

General Queries While Buying Nickel 201 Washers

High rejection rate

No control on quality and testing

Non availability

Late deliveries

Poor packaging/ Unprofessional Packing

Poor after sales service

Supply of wrong grades

Material inconsistent with ASTM Standards

Very hard material for use

Poor surface finish

No Mill test report

Dubious Practices

Lack of knowledge

Product fails under high pressure

High pricing of the goods due to supplier commission

Why Choose JF Engg. While Buying Nickel 201 Washers ?

High pressure sustainability

Impeccable surface finish

Product replacement warranty

After sales support and service

World class buying experience

Very quick delivery

Mill test report/ Digital Mill test report in accordance with EN10204 NACE 3.1, NACE 3.2

3rd Party inspection

Government and Private Laboratory Testing

Test certificate from ISO 17025 Standards Laboratory

Same day shipping of the goods

Highest stock in the country

Stringent Quality Testing and Control

Global Network

—————-We Export To —————–

Afghanistan

Albania

Algeria

American Samoa

Andorra

Angola

Anguilla

Antarctica

Antigua And Barbuda

Argentina

Armenia

Aruba

Australia

Austria

Azerbaijan

Bahamas, The

Bahrain

Bangladesh

Barbados

Belarus

Belgium

Belize

Benin

Bermuda

Bhutan

<o

Bolivia

Bosnia and Herzegovina

Botswana

Bouvet Island

Brazil

British Indian Ocean

Brunei

Bulgaria

Burkina Faso

Burundi

Cambodia

Cameroon

Canada

Cape Verde

Cayman Islands

Central African Republic

Chad

Chile

China

China (Hong Kong S.A.R.)

China (Macau S.A.R.)

Christmas Islands (CX)

Cocos (Keeling) Islands

Colombia

Comoros

Congo

Congo Democractic Republic

Cook Islands

Costa Rica

Cote D’Ivoire (Ivory Coast)

Croatia (Hrvatska)

Cuba

Cyprus

Czech Republic

Denmark

Djibouti

Dubai

Dominica

Dominican Republic

East Timor

Ecuador

Egypt

El Salvador

Equatorial Guinea

Eritrea

Estonia

Ethiopia

Falkland Islands

Faroe Islands

Fiji Islands

Finland

France

French Guiana

French Polynesia

French Southern Territories

Gabon

Gambia, The

Georgia

Germany

Ghana

Gibraltar

Greece

Greenland

Grenada

Guadeloupe

Guam

Guatemala

Guinea

Guinea-Bissau

Guyana

Haiti

Heard and McDonald Islands

Honduras

Hungary

Iceland

India

Indonesia

Iran

Iraq

Ireland

Israel

Italy

Jamaica

Japan

Jordan

Kazakhstan

Kenya

Kiribati

Korea

Korea, North

Kuwait

Kyrgyzstan

Laos

Latvia

Lebanon

Lesotho

Liberia

Libya

Liechtenstein

Lithuania

Luxembourg

Macedonia

Madagascar

Malawi

Malaysia

Maldives

Mali

Malta

Marshall Islands

Martinique

Mauritania

Mauritius

Mayotte

Mexico

Micronesia

Moldova

Monaco

Mongolia

Montserrat

Morocco

Mozambique

Myanmar

Namibia

Nauru

Nepal

Netherlands Antilles

Netherlands

The New Caledonia

New Zealand

Nicaragua

Niger

Nigeria

Niue

Norfolk Island

Northern Mariana Islands

Norway

Oman

Pakistan

Palau

Panama

Papua new Guinea

Paraguay

Peru

Philippines

Pitcairn Island

Poland

Portugal

Puerto Rico

Qatar

Reunion

Romania

Russia

Rwanda

Saint Helena

Saint Kitts And Nevis

Saint Lucia

Saint Pierre and Miquelon

Saint Vincent / Grenadin

Samoa

San Marino

Sao Tome and Principe

Saudi Arabia

Senegal

Seychelles

Sierra Leone

Singapore

Slovakia

Slovenia

Solomon Islands

Somalia

South Africa

South Georgia

Spain

Sri Lanka

Sudan

Suriname

Svalbard / Jan Mayen Island

Swaziland

Sweden

Switzerland

Syria

Taiwan

Tajikistan

Tanzania

Thailand

Togo

Tokelau

Tonga

Trinidad And Tobago

Tunisia

Turkey

Turkmenistan

Turks And Caicos Islands

Tuvalu

Uganda

Ukraine

United Arab Emirates

United Kingdom

United States

United States Minor Outlying

Uruguay

Uzbekistan

Vanuatu

Vatican City State (Holy See)

Venezuela

Vietnam

Virgin Islands (British)

Virgin Islands (US)

Wallis And Futuna Islands

Western Sahara

Yemen

Yugoslavia

Zambia

Zimbabwe

------------------------------------------------------------------------------------------------------------------------------

For More Information About Nickel 201 Washers please call +91 22 2385 6385 / 2385 638 or send an email to info@jfengg.com